3D filament

3D printer filament is long thermoplastic threads used for fused deposition modelling 3D printers.Few important types of filaments are ABS filament, PLA filament, PETG filament, PETT filament, Nylon filament, PVA filament, sandstone filamnet, wood filament, metal filament. These are usually spooled into a reel for storage and printer feeding. The thread is fed into the 3D printing machine which heats the plastic to a temperature where it becomes flexible, this allows the printer to deposit the material in the desired shape. The plastic solidifies into the desired model when cooled.

Types of filaments

ABS Filament 3D filament

ABS(Acrylonitrile Butadiene Styrene) is a thermoplastic-based on oil. It is preferred for its strength, anyone who has used Lego bricks would know how tough it is. Other uses of ABS are golf club heads, protective headgear, support blocks, wheel covers, musical instruments and kitchen utensils.

Pros:

· Heat resistant: With a heat resistance of about 110°C, ABS is used for making functional parts.

· Strength: It offers very high tensile and impact strength.

· It’s very flexible and lightweight

Cons:

· Prone to warping and hence is very hard to use for hobbyists

· Release unpleasant fumes called VOCs which can be very unhealthy in poorly ventilated places.

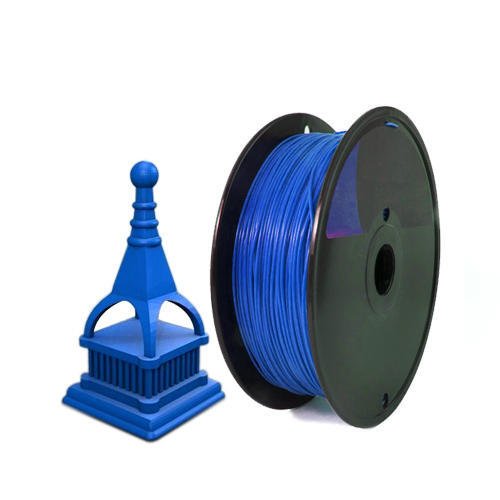

PLA Filament 3D filament

PLA(Poly Lactic Acid) 3D printer filament is made from organic materials, hence it does not produce any fumes and is much safer to use than ABS. It is also less prone to warping, hence making it a very popular choice. It is used for shrink wraps (as it constricts under heat), decomposable packaging material, and biodegradable medical devices, including screws, pins, plates and rods that are designed to biodegrade within 6 to 12 months).

Pros:

· Environmental Friendly

· User friendly, does not require a heated bed and is less prone to warping

· Safe for use in the food and medical industry

Cons:

· Low heat resistance, begins to soften at 60°C

· Comparatively low strength

· It can degrade quickly when exposed to direct sunlight

PETG Filament 3D filament

PETG filament is a derivative of PET(Polyethylene terephthalate) with the addition of Glycol to it at the molecular level which gives it slightly different properties from PET. It is resistant to heat, impact and solvents giving it a wide range of industrial uses. It is an ideal 3D printing filament as the layers have strong adhesion and have minimum deformation during printing.

Pros:

· PETG filament is recyclable.

· Non-toxic and odourless emissions.

· Easily coloured: PETG is transparent making it easy to blend colours in it.

Cons:

· Printing supports can be difficult to remove due to the strong adhesion of PETG filament.

· Prone to scratches

· Prone to take in moisture quickly which makes it brittle, hence requires proper storage

PETT 3D Printer Filament

PETT filament stands for Polyethylene coTrimethylene Terephthalate filament, another derivative of PET much less famous than its counterpart PETT.

Pros:

· Low Shrinkage: Being a high-temperature filament like ABS, it is unique in the aspect that it has a low shrinkage factor, making it less prone to warping.

· Excellent layer adhesion

· Water clear: The material retains a large portion of its clarity even when the model is printed in thick layers.

Cons:

· Not popular: The number of companies selling this filament is very less

· Expensive

Nylon Filament 3D filament

This is rare among other types of filaments. Nylon filament offer strong and durable printed parts. It is also flexible, light, wear-resistant, and less brittle than both ABS and PLA.

Pros:

· Nylon filament is high in Strength and durability

· Wear-resistant

· Filament can be re-melted and used again without any loss of bonding

Cons:

· Nylon is highly hygroscopic and needs to be stored properly

· Has a high melting temperature

PVA 3D Printer Filament

Polyvinyl alcohol (PVA filament) is a long-chain polymer composed of vinyl alcohol monomers. It is used usually as a support material and hence is best used with printers that at least have dual extruders.

Pros:

· It is easily water-soluble hence great as a support material

· Biodegradable and non-toxic

Cons:

· Needs to be stored in an airtight container to avoid degradation

· Can cause clogging of the nozzle

· Costlier compared to other filaments

Sandstone Filament

This 3D printer filament is a composite of PVA and fine milled chalk. Prints made using this filament give the appearance of sandstone or ceramic which no other 3d printing filament can provide. The excellent aesthetics provided by this material is useful to make architectural and landscape models.

Pros:

· No heated bed required to print

· Excellent stone-like aesthetics

· Low tendency to warp

Cons:

· Abrasive in nature and can wear down the nozzle

· Brittle and can break during printing if care not taken

· Expensive

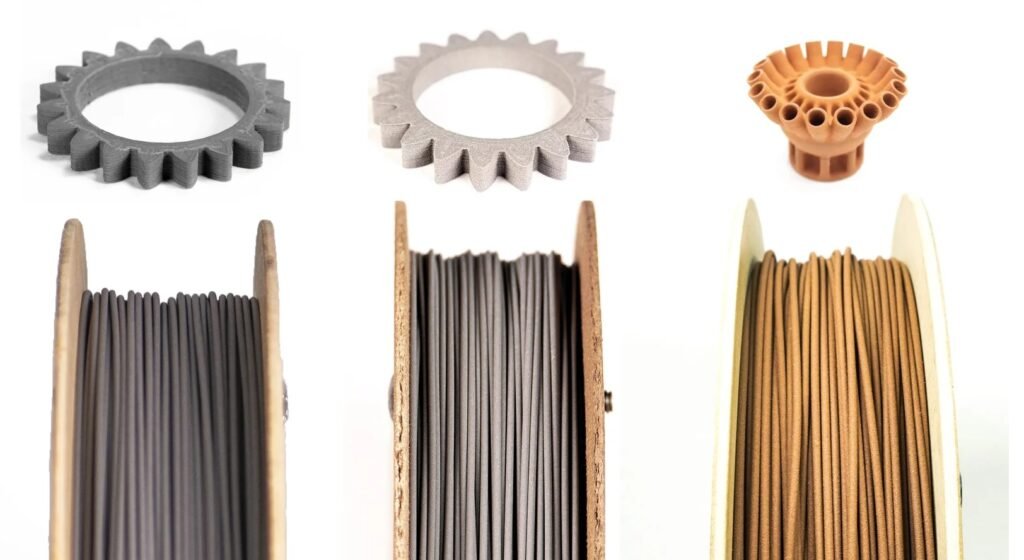

Wood Filament

This is another composite filament, made of PLA infused with fine powdered wood materials like wood dust, cork, bamboo, or other powdered wood derivatives. This filament allows the printing with a wood-like finish.

Pros:

· Much less abrasive than its composite filament counterparts

· Low tendency to warp or shrink and easy to work with

· Largely biodegradable

Cons:

· Brittle and can break easily during the print

· Printing needs to be monitored carefully as wood is flammable and can burn in the higher temperature environment of the printer if left inside for too long. Remaining types of filaments are listed as,

Metal Filament

This 3D printer filament is made using PLA infused with fine metal powders like brass, bronze, copper, or stainless steel. The filament usually consists of about 80% metal and 20% plastic. This is a much more economical method of printing metal-like structures than traditional full metal 3d printing.

Pros:

· Finished products have a metallic lustre

· Heated bed not required

· Resistant to shrinking and warping

Cons:

· More expensive than plastic filaments

· Lacks flexibility and is very brittle

· Structures become very heavy so overhang support is poor

Magnetic Iron 3D Printer Filament

These are made using infusing finely ground iron powder with PLA. The iron in the filament allows printing models that are ferromagnetic, and hence, the models can interact with magnets.

Pros:

· Easy to work with and produce a good print even in less than ideal situations

· Magnetic properties allow for creative applications

Cons:

· Can cause abrasion to the printer nozzle

· Rigid and brittle

· Not many choices in the market

These were the most of the types of filaments. Get your First 3D Print for FREE – Click Here

Refer wikipedia page for more details.