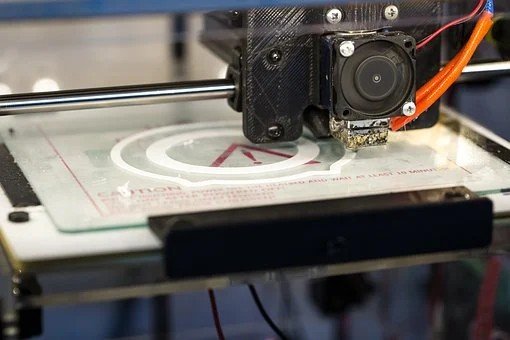

What is 3D Printing?

Introduction

Since time immemorial, humans have always had a knack for creating. From making wooden spears to mammoth structures of steel, we have come a long way. Making something new has always been a long, tedious process involving a lot of trial and error, oftentimes requiring big expensive devices to be realized. But with the advent of 3D printing, we have stepped into a new era of manufacturing. Now even individuals can realize bespoke objects quickly at a very affordable cost. The wastage of material and cost of trial and error has decreased significantly using a 3D printer as now designs can be perfected using various software before being printed out.

Traditional methods for 3D printing/manufacturing

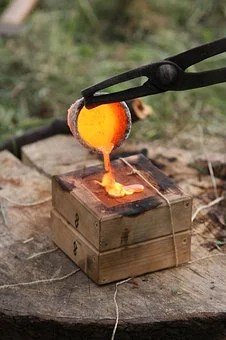

Casting manufacturing process

In casting, metal is melted and then poured into a mold and is allowed to solidify. In this process, the metal takes the shape of the mold. The same mold can be used again for making more identical shapes in a consistent and fast manner. There are a wide variety of methods of casting, with each having a different use case. Some examples are sand casting, plaster casting, die casting and permanent mold casting.

Forming manufacturing process

This contains a wide variety of techniques that involves working with solid metal. One of the most ancient and famous examples is forging, in which the metal is simply beaten into the desired shape.

Subtractive manufacturing process

This is a process in which material is removed from an object to reach the final product, commonly done by a process called Computer Numerical Control (CNC) machining. A milling process is employed and a variety of cutting tools shape the object to the desired final product.

Additive manufacturing process

This involves adding successive layers of material to create an object. For example, painting is an additive process as a painter adds paint to the canvas to create the final product.

How 3D printing is different from traditional methods of manufacturing?

3D printed products can be endlessly customized at no extra cost. The unique nature of the process ensures that for similar objects, changing some details according to the end-user comes at no additional process cost.

Products developed through 3D printing are designed through software, this has enabled a level of complexity to be applied to designs that were not possible or were very tedious to be made by other methods of manufacturing.

Steps of 3D Printing:

- Create a 3D model: You can create a 3D design using CAD software or use a 3D scanner to obtain the geometry of the object to be printed.

- Convert CAD model to STL format: STL format is suitable for 3D printing as it is easy to be used by 3D machines and software. In this form, the three dimensional surface of the model is represented as a collection of planar triangles. The model will have a higher resolution with an increase in the number of triangles used to build the model albeit with a cost of bigger file size.

- Slice the model into layers: This is an important step as this determines the quality of the object and the amount of time the 3D printer will require to print the object. A smaller layer height will entail a higher quality end product but a higher print time. It is also important to check if the model would require support to be printed along with it. These are useful for delicate features like overhangs, internal cavities and thin wall sections which might break during the construction process.

- Construct the model: This is the step where the actual printing takes place. The 3D printer builds one layer at a time with the material fed into it. This is a fairly autonomous process and requires little human intervention.

- Clean and finish the model: After the printer has built the whole model, we detach the supports (if any) and improve the appearance by sanding, sealing and/or painting.

How to design in 3D?

To begin with 3D printing, a 3D digital model is needed, which can be created using a variety of 3D software. They have different levels of complexity and different licenses supporting different work cases.

3D design software:

- Free software: SketchUp, Blender, FreeCAD, Wings 3D

- Commercial software: AutoCAD, Solidworks, Cinema 4D, Catia

- A digital copy of a real physical object can also be obtained through 3D scanning.

- Another possibility is to download a 3D model from the internet, these can be ready to print or require some small corrections.

3D Printing Industry:

Nowadays 3D printing is becoming a widely used technology in industries due to its use in “rapid prototyping”. Industries can quickly test out new products by producing prototypes in a fast and efficient way.

Some industries where 3D printing technology is widely used are:

- Medicine: One of the early adopters of 3D printing technology, the medical sector found a lot of uses of this technology, from bioprinting to making prosthetics. Due to the versatile nature of the technology, it became easier to create parts that are uniquely fitting to a certain individual. Children needing prosthetics often needed to wait as they would outgrow the part made for them but now those parts can be printed for them every few months. The ability to print porous 3D parts made it so that printed orthopaedic implants would be less likely to be rejected by the receiver’s body.

- Architecture/Construction: 3D printing lets architects print out accurate demonstration models of their plans. This visualization enables better planning and innovation. 3D printing can also be used directly for construction. The first fully completed residential building was constructed in Yaroslavl, Russia in 2017. 600 elements of the walls were printed in a shop and assembled on-site, followed by completion of the roof structure and interior decoration for a total area of 298.5 sq meters (3213 sq ft). It passed all building requirements and now a family lives in it, showing that 3D printing can have direct applications too.

- Robotics: The ability to design and create custom parts quickly makes 3D printing a perfect choice for the robotics industry. The parts printed are economical enough that a hobbyist can afford to try his hands on creating something new by himself. The accuracy of the printing ensures that even bespoke parts can be created with negligible error. Click here to visit wikipedia page of 3d printing.

3D Printing Technology:

There are several types of 3D printing, each varying in material selection, durability, manufacturing speed, surface finish and cost. They are listed as follows:

- Stereolithography(SLA)

- Selective Laser Sintering (SLS)

- Polyjet

- Digital Light Processing (DLP)

- Multi Jet Fusion (MJF)

- Fused Deposition Modeling (FDM)

- Direct Metal Laser Sintering (DMLS)

- Electron Beam Melting (EBM)

Get your First 3D Print for FREE – Click Here